If you are concerned about thermally induced stresses in

your design, you will want to run a thermal analysis to determine the

temperature distribution. Then, map the temperature results to a subsequent structural

analysis.

Mechanical Event Simulation (MES) allows a user to apply

such temperatures automatically, whether from a steady-state or transient heat

transfer analysis.

If you have previously run a transient thermal analysis, you

may want to ensure that the mapping algorithm used for transferring the

temperatures to an MES analysis has worked as expected. After all, you could be

using different mesh sizes for each analysis type, and the nodal temperatures

may not map one-to-one from a transient thermal analysis to an MES analysis.

So how do you check if the mapping was done correctly?

Here is how:

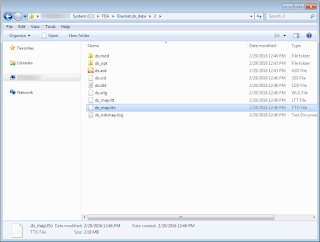

In this example, the

FEM file is located in the following folder (C:\FEA\Bracket.fem)

Let’s

say that, in Design Scenario 1, you conducted a Transient Heat Transfer

analysis on an Assembly using a 100% mesh size.

Then, you created a second Design Scenario as an MES

analysis and meshed it with a 50% mesh size. You then applied the thermal loads

within the Thermal tab of the

Analysis Parameters dialog.

Before running the MES analysis, simply perform a “Check Model”

operation. This action creates the solid mesh and decodes the geometry, loads,

and constraints. If you look in the Design Scenario 2 folder (C:\FEA\Bracket.ds_data\2), you will now

see a file named “ds_map.tto”, which

is a transient temperature output file mapped from Design Scenario 1 to Design

Scenario 2.

At this point, change the analysis type from MES to

Transient Thermal, creating a 3rd Design Scenario. Keep the same

mesh size (50%) as used in the MES analysis.

Using Windows Explorer, copy the file “ds_map.tto” from “C:\FEA\Bracket.ds_data\2”

to “C:\FEA\Bracket.ds_data\3”. Then,

rename the copied file “ds.tto” (deleting “_map” from the name).

Within Simulation Mechanical perform a “Check Model” operation

for the 3rd design scenario, which is the second transient thermal

analysis, without applying any loads or constraints.

In the Results environment for design scenario 3, you will

now be able to see the temperature results that were mapped from Design

Scenario 1 (utilizing a 100% mesh size) to Design Scenario 2 (utilizing a 50%

mesh size).