The

temperature distribution in a part can cause thermal stress effects (stresses

caused by thermal expansion or contraction of the material). Examples of this phenomenon include

interference fit processes (also called shrink fits), where parts are mated by

heating one part and keeping the other part cool for easy assembly. Another example is thermal creep, which is

permanent deformation resulting from prolonged application of a stress below

the elastic limit. An example of this is

the behavior of metals exposed to mechanical loads and elevated temperatures

over time.

Thermal

stress effects can be simulated by coupling a heat transfer analysis

(steady-state or transient) and a structural analysis (static stress with

linear or nonlinear material models or Mechanical Event Simulation [MES]). The process consists of two basic steps:

- Perform a heat

transfer analysis to determine the temperature distribution.

- Directly input the

temperature results as a load in a structural analysis to determine the

stress and displacement caused by the temperature loads.

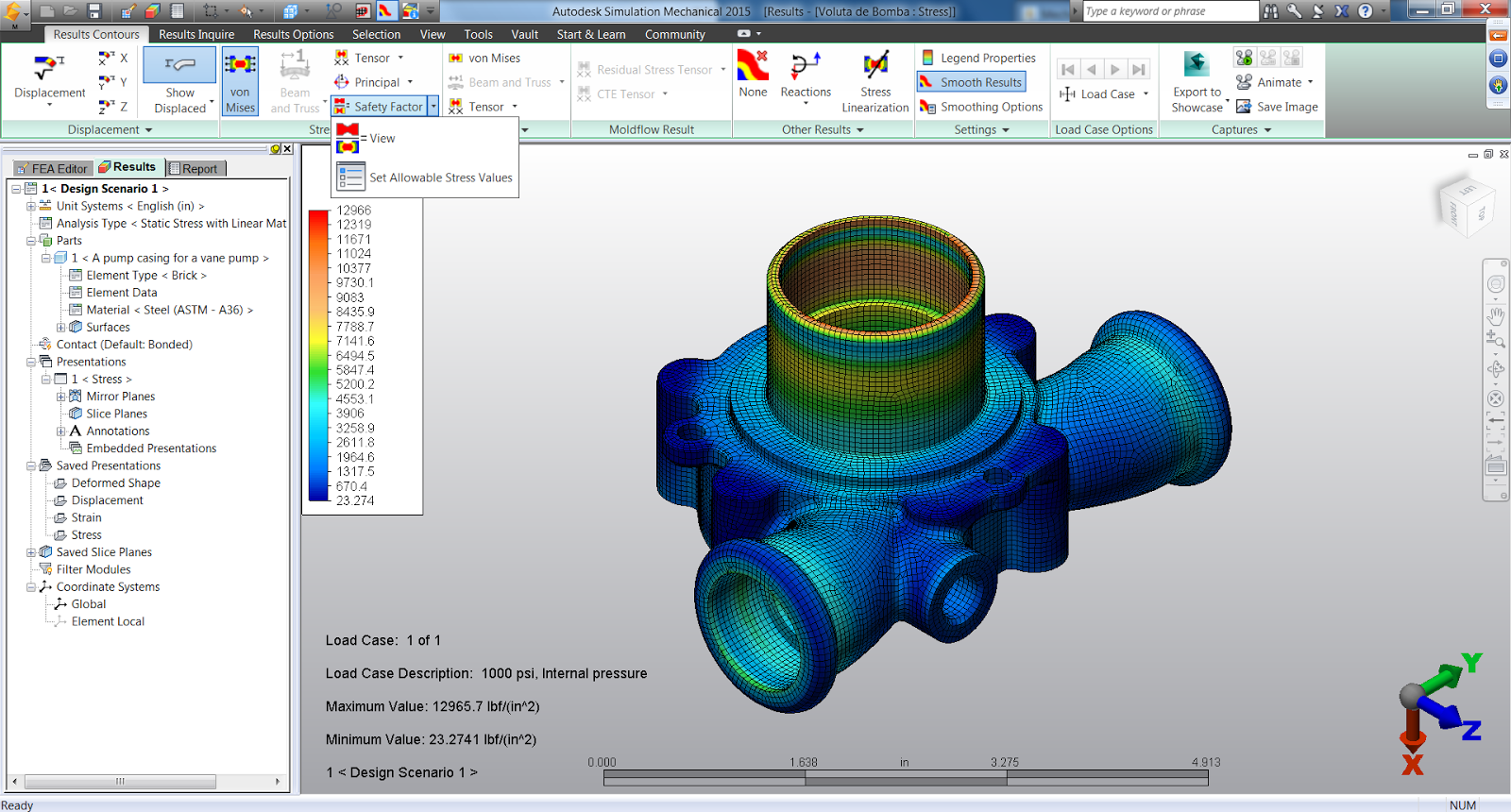

For

example, a thermal stress analysis of a transistor and heat sink assembly was

performed as follows:

- A steady-state heat

transfer analysis was performed to obtain the temperature distribution

(see Figure 1).

Figure

1: A transistor and heat sink model with

temperature distribution results from a steady-state heat transfer analysis.

|

||

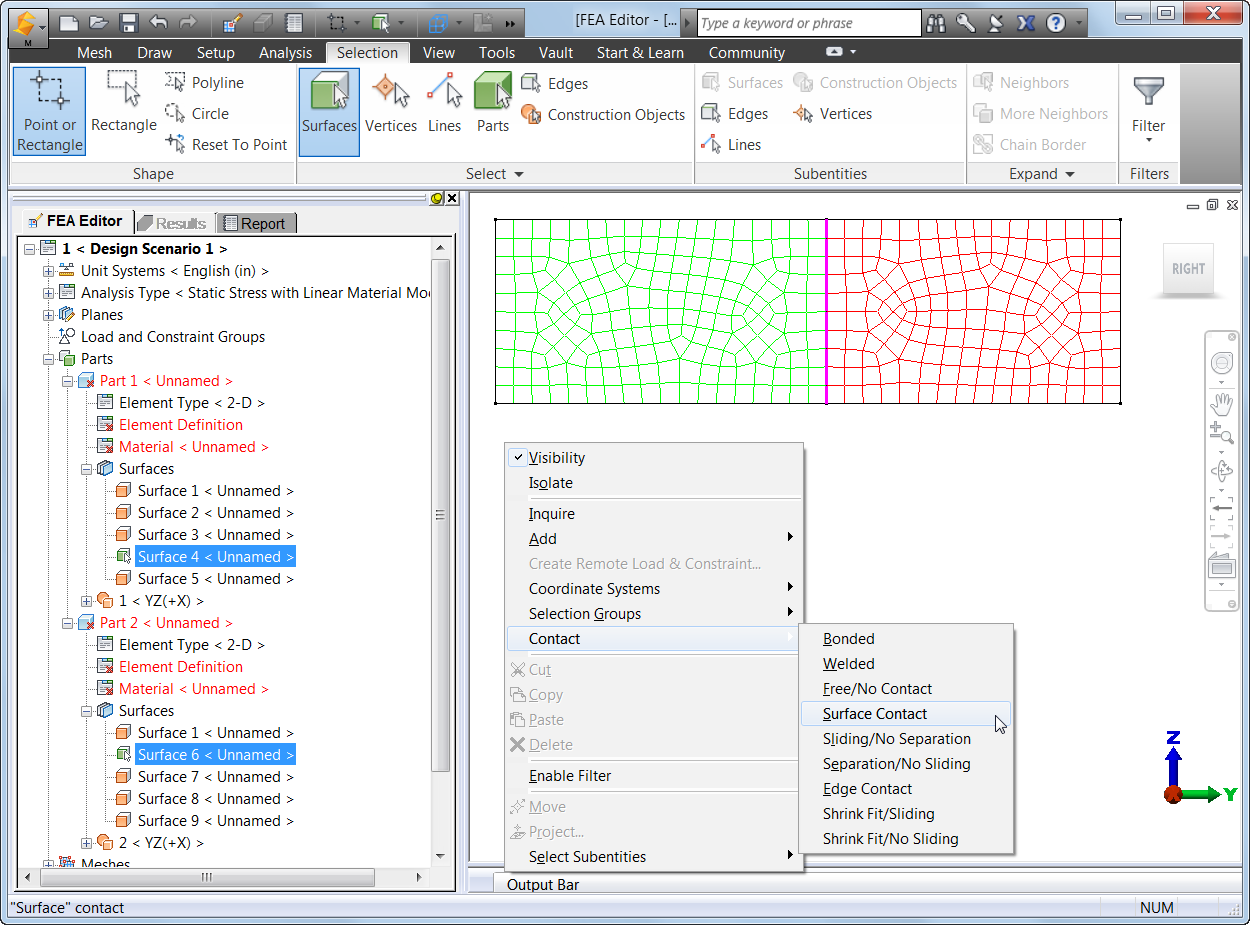

- In the FEA

Editor environment of Autodesk Simulation Mechanical, the analysis

type was changed for a structural analysis. In this case, static stress with linear

material models was used.

- Constraints were

specified for the structural analysis by fully fixing the two bottom

surfaces of the model. Additional

structural loads (such as forces, pressures, and gravity) could have been

added if desired; however, for this example, the only loads were the

temperatures from the heat transfer analysis.

- On the

"Multipliers" tab of the "Analysis Parameters" dialog,

a load case multiplier of "1" was specified in the

"Thermal" column so that thermal effects would be included in

the structural analysis (see Figure 2).

|

|

Figure

2: A load case multiplier was specified to

include thermal effects in the structural analysis.

|

- On the "Thermal"

tab of the "Analysis Parameters" dialog, "Another Design

Scenario in loaded file" was chosen from the pull-down menu of

options in the "Source of temperatures" field. "1 – Design Scenario 1" was

chosen from the pull-down menu of options in the "Use temperatures

from Design Scenario" field was used to specify the location of the

temperature results file from the previous steady-state heat transfer

analysis (see Figure 3).

|

|

Figure

3: The "Thermal" tab of the

"Analysis Parameters" dialog was used to specify the Design

Scenario that would be used as input to the static stress analysis with

linear material models.

|

- The static

stress analysis with linear material models was run and then the results,

including thermal stress effects, were displayed in the Results

environment (see Figure 4).

|

|

Figure

4: Displacements (left) and stresses (right)

in the transistor and heat sink assembly due to temperature loads, displayed

in the Results environment.

|

Thus,

the ability to couple heat transfer and structural analysis capabilities

provides an easy and convenient way to simulate thermal stress effects.